Objectives: process-microstructure-properties relationships

Approach: elaboration, multiscale microstructural analyses and numerical modelling

Means : spark plasma sintering, déformation+TTH, casting, additive manufacturing

Materials : steels (316L, 304L), copper alloys

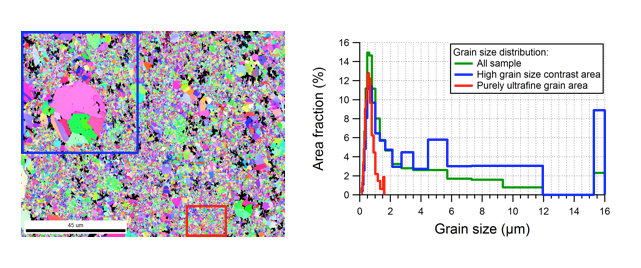

CG: (a) EBSD orientation maps and (b) associated grain size distribution for the whole

sample, in a large grain size contrast area (blue delimited area) and in a purely UFG area

(red delimited area).

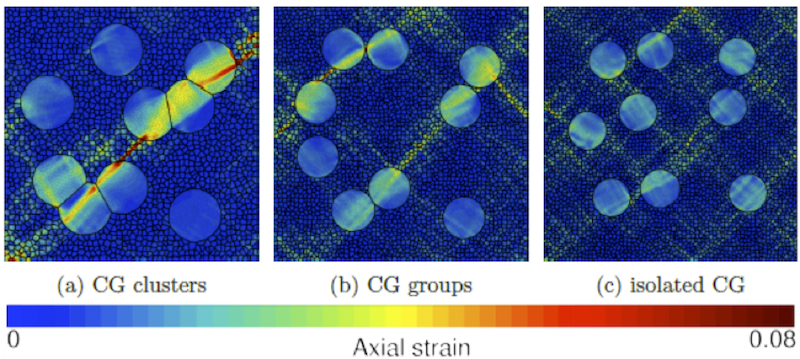

Tensile test up to 1% total strain (plane stress boundary conditions).