Team members : V. Nachbaur (MCF), S. Jouen (MCF)

Mineral resources play a key role in the technologies associated with the energy transition. In particular, the growing deployment of electric vehicles means that the use of certain elements must be considered a geopolitical issue. This is particularly the case for the elements present in lithium-ion batteries such as cobalt, lithium, nickel, manganese or graphite, whose growing need has revealed interdependencies and vulnerabilities.

In this context, the GPM laboratory, within the framework of projects funded successively by the ESP Carnot Institute and the Normandie Region, has developed a new approach, with a low environmental footprint, for recycling lithium-ion batteries. This process, patented in 2021, is based on a solvothermal treatment whose advantages over existing processes (pyrometallurgy and hydrometallurgy) are

- It is carried out at relatively low temperature (< 300°C)

- It does not use any acid or base, but only low cost solvents with low environmental impact

- That the solvent can be reused several times.

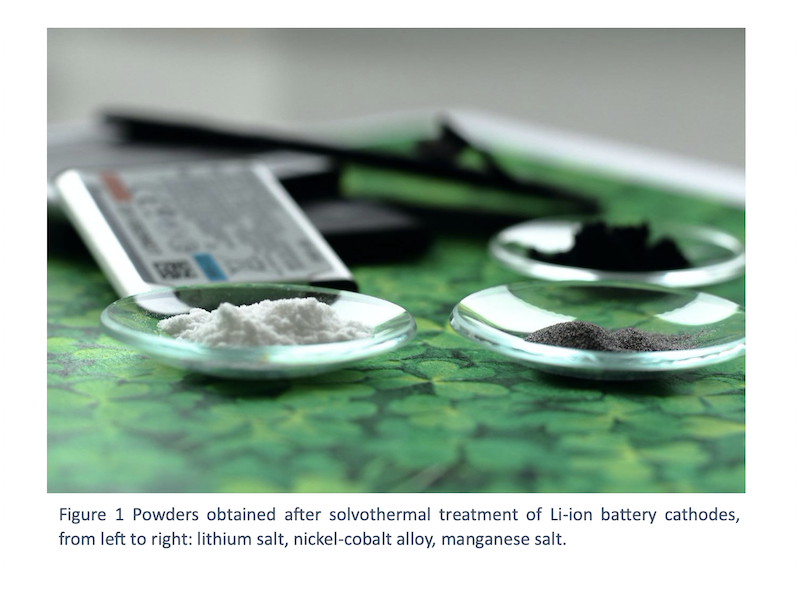

At the end of the solvothermal treatment, the various valuable elements are obtained in the form of easily separable powders (Figure 1), either in the metallic state or in the form of hydroxide, oxide or carbonate.

The process developed has been successfully applied to LCO, NCA, NMC, LMO cathode compounds and is currently being adapted to industrial black mass in the framework of a CNRS-funded prematuration project.