Team leader : Benoit Vieille

Team members : B. Vieille (PR), F. Barbe (MCF), L. Taleb (PR), M. Ben Azzouna (MCF), T. Davin (MCF)

Keywords :

- Mechanics of materials, Elasto-visco-plasticity, Cyclic behavior, Fire exposure, Phase transformation,

- Metals, Carbon fiber reinforced composites, Thermoplastics,

- Experimental analyses, Constitutive modeling, Crystal Plasticity

Our research activities contribute to make the link between analyses and developments in the physics of materials (metals, polymers, composites) and mechanical properties in service, particularly on a macroscopic scale. In order to ensure this link on the basis of an understanding of the involved physical mechanisms and by relying on GPM's complementary expertise, multi-scale and multi-physics approaches are favored, both for experimental analyses and for modelling. The detailed understanding of microstructure-properties relationships feeds two main development paths: constitutive models for the design of structures and materials engineering, in particular via lattice structures. The main focus is on investigating structural materials under representative real conditions, that is complex thermo-mechanical loading, up to critical thermal exposure conditions.

Our areas of expertise concern the cyclic elasto-visco-plasticity of materials, the study of damage and the behavior in severe environments, mainly of metals and thermoplastic matrix composites (TP). The activities are developed in two main areas:

- Additive manufacturing (metallic and polymer):

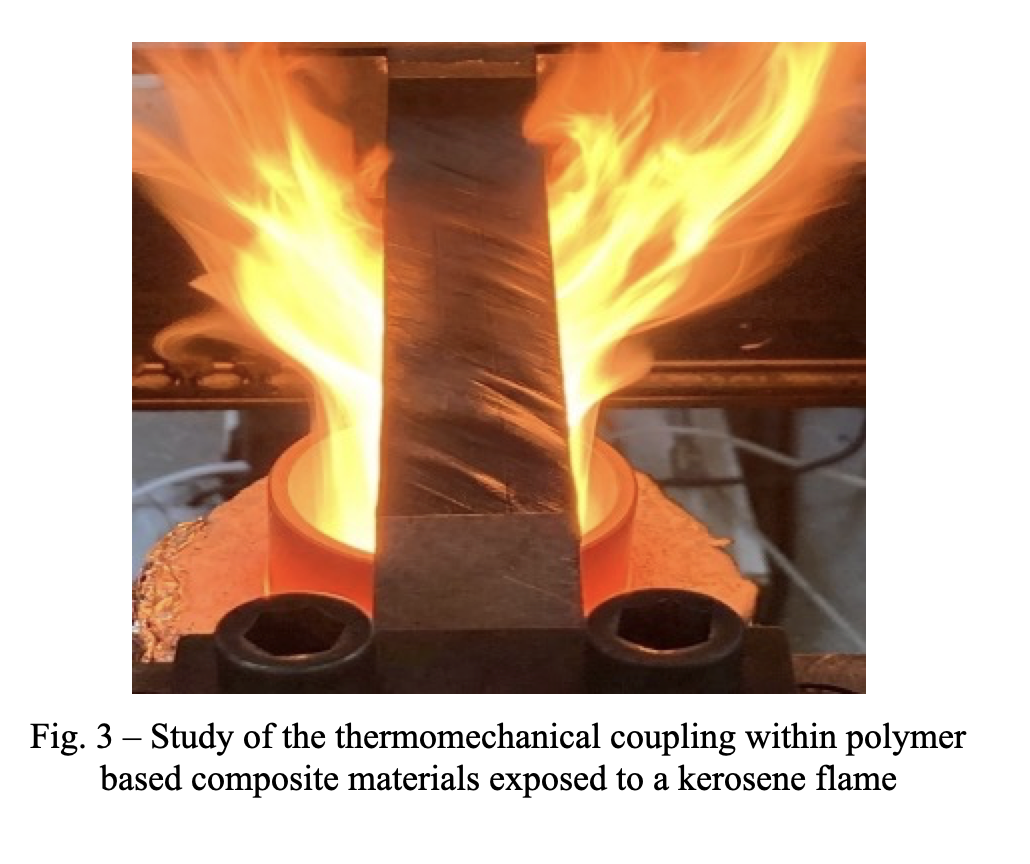

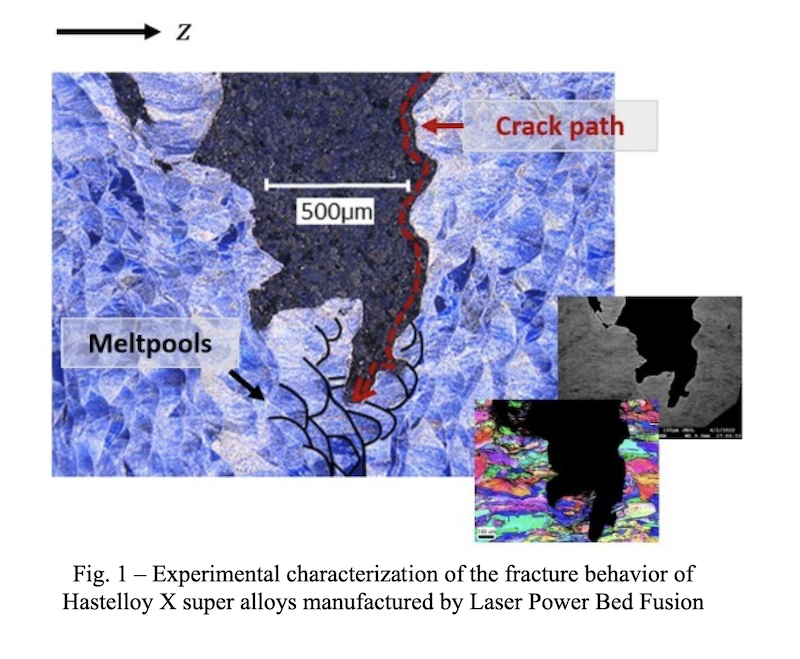

The skills developed for the study of metallic and composite materials will be exploited for the study of materials resulting from AM, which today constitutes a federating research axis within the team and the GPM. Our projects are carried out in collaboration with academic partners from Normandy and industry on two primary issues: (i) understanding the link between process, microstructure and mechanical properties (Fig. 1) and (ii) the mechanical behavior of lattice structures. Both are based on the comparison or the confrontation between the experimental data (conventional and non-standard mechanical tests) and their numerical counterpart. The latter is obtained from (complex) finite element models such as crystal plasticity at the grain scale (Fig. 2). The presence of leading industrial companies (Safran Nacelles, Zodiac Aerospace, Ariane Group, Thales, Airbus Safran Launchers, Renault, Arkema, Dedienne Multiplasturgy, etc.) in Normandy involved in AM enables these research activities to be part of a strong dynamic.

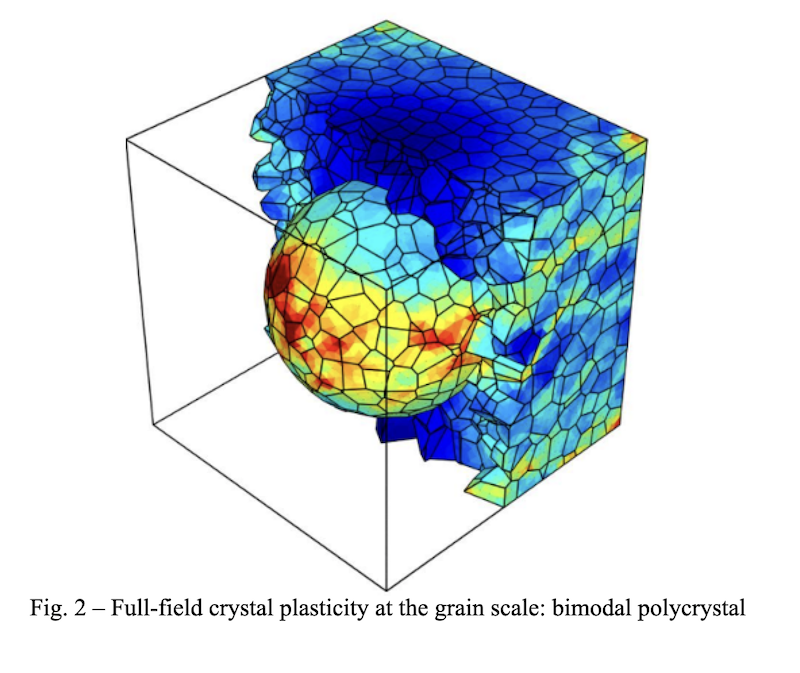

- The fire behavior of materials for aeronautics:

We have developed experimental characterization means dedicated to the multi-physical analysis of the behavior of mechanically stressed composites under kerosene flame (Fig. 3), adopting a multi-scale approach (micro-meso-macroscopic). Our test bench will eventually enable us to reproduce as closely as possible the critical service conditions (fire in an aircraft engine environment). The multidisciplinary nature of the project (combustion, thermal transfers, mechanics and chemistry of materials) is dealt with through collaborations with the Disordered Systems and Polymers department, the CORIA and LCMT laboratories. Collaborations recently initiated with Safran Nacelles and Daher confirm the relevance of the resources/skills developed and provide the GPM with rare expertise. From this experimental specificity, numerical models are also being developed to predict the thermo-mechanical behavior of organic composites in a wide range of temperatures (up to the thermal decomposition of the matrix and the oxidation of fibers).